Double Belt Lamination Technicon Acoustics

Technicon Acoustics adds double-belt lamination capabilities

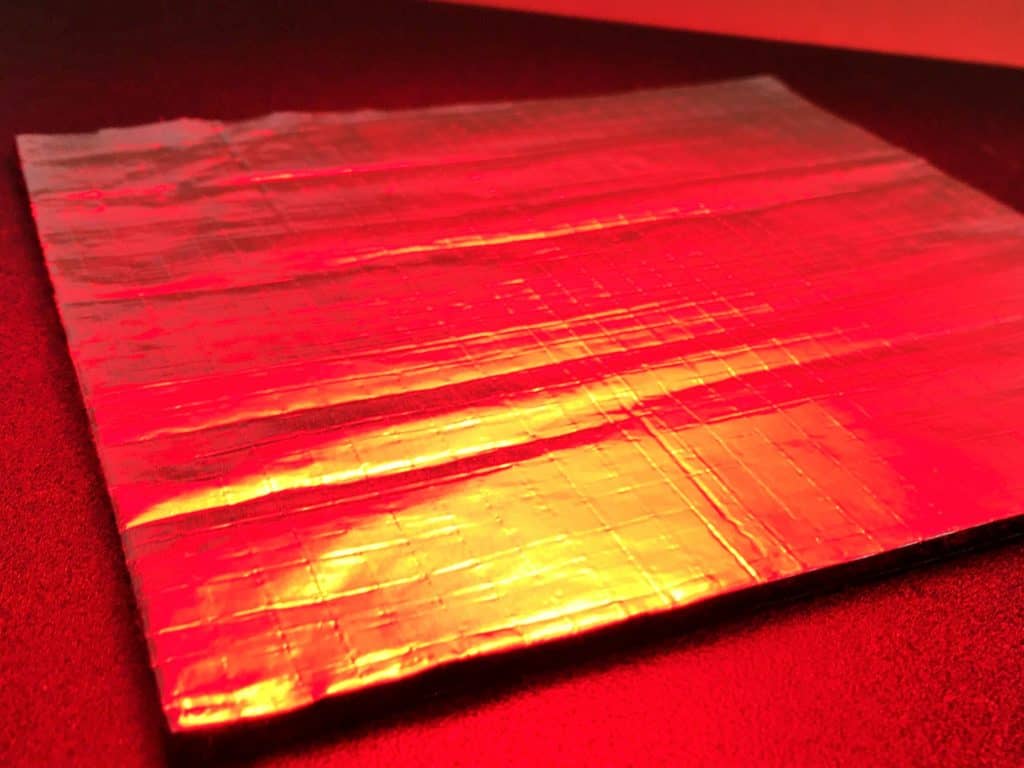

At Technicon, we continue to invest in the latest manufacturing technologies to ensure we can make high quality materials as effectively as possible. Our newest equipment is a new double belt lamination process. This line has independent heat zones on the top and bottom as well as infrared heating on the in-feed side of the machine. This gives us the ability to laminate multi-layer materials in one pass as well as the ability to laminate new materials that will expand our product line.

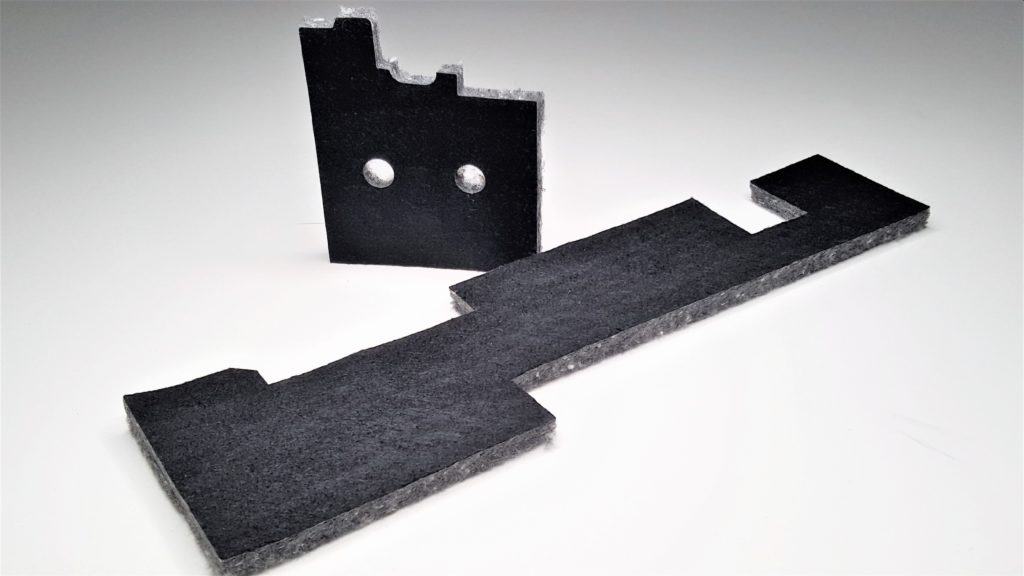

PF-091 Tech Shield ™

Technicon Acoustics, located in Concord, NC is the leading manufacturer in Acoustic and Thermal solutions for OEM’s across North America. We design, develop, and deliver parts and materials that absorb, block and isolate sound and thermal energy.

For more information about our Acoustic and Thermal fabrication capabilities, please visit our capabilities page.