A Closer Look at Sound Damping vs. Absorption

Leave a CommentAcoustic vibration or acoustic energy—more commonly referred to as noise—can be mitigated or eliminated using sound damping or sound absorption techniques. Damping reduces acoustic vibration within any type of structure, wall, or system. In contrast, sound absorption works to dissipate airborne acoustic energy or sound waves. Though different, both achieve the same goal of mitigating unwanted noise.

What is Sound Damping?

Damping removes vibration energy from a structure or system by eliminating the dynamic stresses associated with vibration. Installing appropriate sound damping measures ultimately adds to the wear or fatigue life of structural or machine components.

A greater understanding of the damping function requires a closer examination of how vibration works:

- Vibration travels through different materials at varying levels of intensity. When vibration frequency is equivalent or similar to the natural frequency of a material, it results in amplification.

- Frequency amplification makes vibrations harsher, more jarring, or louder.

- Applying damping materials to substrates that amplify vibrations alters the resonating frequency, reducing the impact of vibration on the system and its components.

The level of damping provided by each type of damping material relates to the material’s damping coefficient. The damping coefficient measures the material’s capacity to produce “bounce back”—or return energy to a system or structure. Materials with lower damping coefficients produce higher bounce back, while those with a higher damping coefficient reduce unwanted vibration or shock by soaking up the vibrational energy. Of note, this process produces a small amount of heat.

Common materials used in damping usually include viscoelastic materials, such as PVC and constrained layer foam composites.

What is Sound Absorption?

When sound waves strike any surface, some of those waves pass through the material and others reflect or bounce off of the surface. Materials with a harder, less porous surface tend to produce a higher level of reflection, while porous materials allow for greater absorption. Acoustic absorption uses porous materials to line hard surfaces that typically reflect sound or airborne noises, such as those produced by:

- Heavy machinery

- Engines

- Power tools

- Generators

Sound absorbers contain porous materials like foam or blended fiber that keep sound waves from reflecting back into open spaces. Lining harder materials with absorbers like polyester fiber, polyester foam, or polyether foam reduces ambient noise produced by sound reflection.

Applications of Acoustic Components for Enhanced Performance

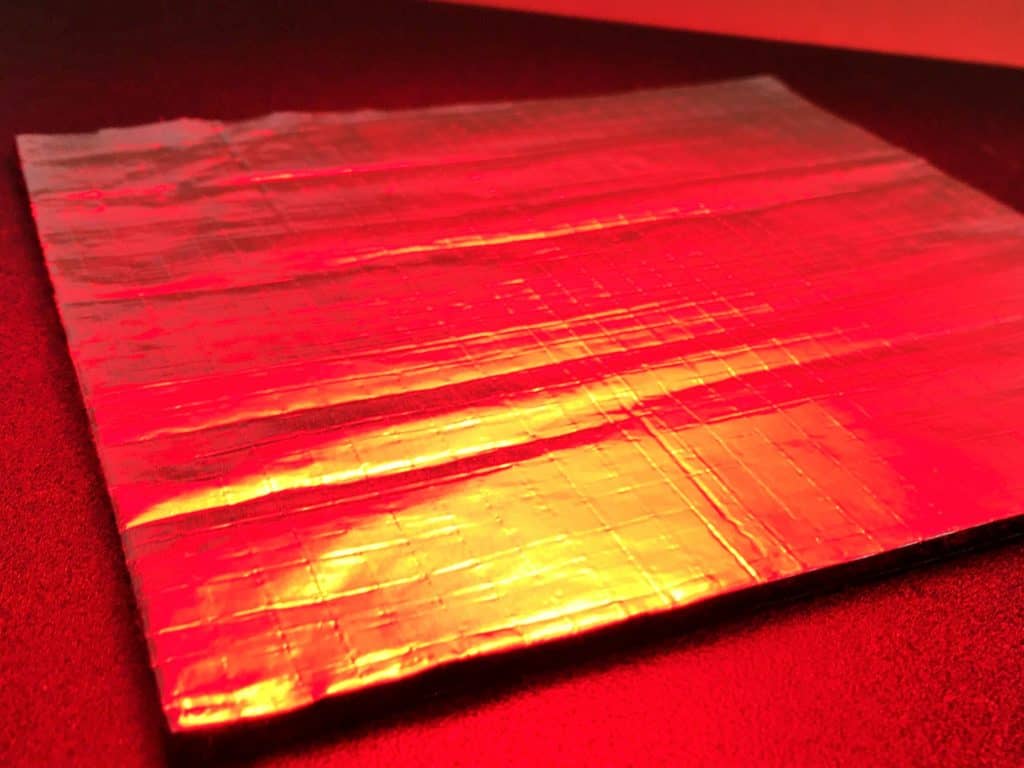

Technicon uses a variety of sound absorbing and sound damping materials to mitigate acoustic vibration and noise in a broad range of applications. Our acoustic foam—often referred to as sound absorbing foam or soundproofing foam—is available in a variety of thicknesses and facing configurations for both functionality and aesthetic purposes.

These products will reduce ambient noise in applications such as:

- Machine enclosures (generators, air compressors, water pumps, etc.)

- Engine compartments

- Truck and heavy equipment cabs

- Home appliances

- Medical equipment

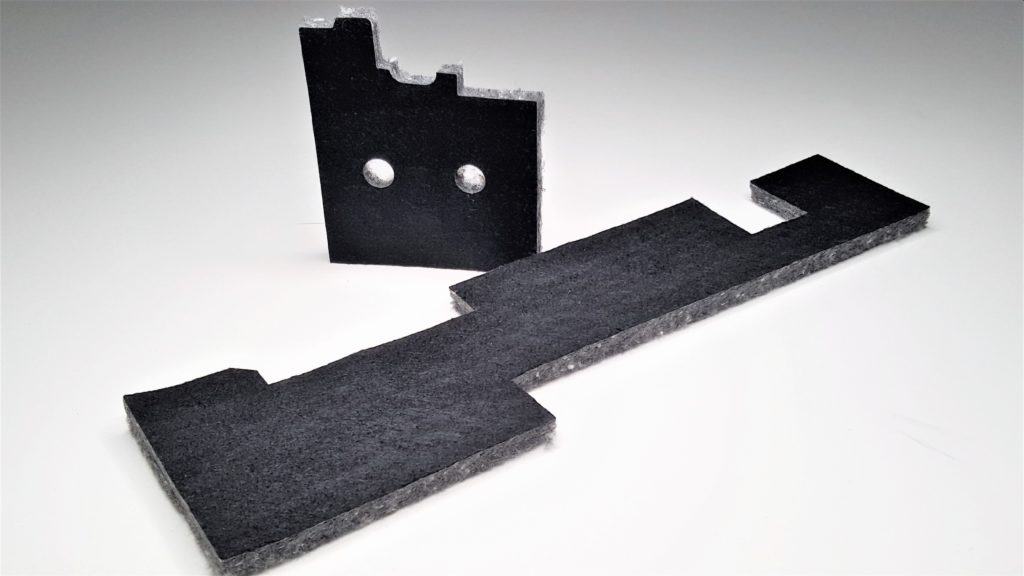

We also provide sound damping materials. Application of our vibration damping composites control vibration fatigue and structure-borne noise, often in combination with sound absorbers to reduce airborne noise as well.

Let Our Acoustic Specialists Help You

Whether your specific application requires a reduction in acoustic vibration through sound damping or noise reduction provided by sound absorption, Technicon Acoustics has the solution. We are a leading producer of both acoustic and thermal solutions for a broad range of original equipment manufacturers (OEMs) throughout North America.

Contact us or request a quote to learn more about the sound damping and sound absorption solutions available from Technicon.