The Best Marine Noise Reduction Materials

Boat manufacturers need to use high-quality noise-reduction materials to improve boat quality, safety, and passenger comfort. A quieter environment on board is one of the significant factors potential customers consider when buying a boat, and many will pay to have the engine room as silent as possible.

Boat manufacturers use specialized marine noise reduction materials to create a more comfortable experience for passengers and crew. In particular, polyester fibers are more friendly to high-moisture marine environments and provide better noise reduction than traditional polyurethane foam.

Learn more about the best marine noise reduction materials, other noise reduction strategies, and the solutions available from Technicon Acoustics.

How Marine Noise Reduction Materials Affect Noise Pollution

Excessive noise from pleasure boats, custom yachts, and military craft disturbs those on board, on other watercraft, and on the shoreline. The National Association of State Boating Law Administrators (NASBLA) has set safe boating standards for acceptable noise levels to help deal with marine noise pollution.

The maximum sound level for boats with engines manufactured before 1993 should be at most 90 dBA, and the limit is 88 dBA for those manufactured after January 1, 1993. These noise levels should be tested per SAE J2005-Dec 91 while the boat is stationary at the dock. Additionally, no boat should operate with noise levels exceeding 75 dBA for shoreline users, per SAE J1970-Dec 91 standards.

To meet these standards for safe, comfortable operation, boaters need easy-to-apply noise reduction materials and processes.

Marine Noise Reduction Materials and Strategies

The following are some of the most common noise-reduction materials and strategies used on boats:

- Polyester Fiber: Polyester fiber dampens and minimizes sound transmission when applied inside box compartments. Lining the engine compartments or genset interior walls with polyester fiber composites significantly reduces the noise generated by this equipment. Polyester fiber works better than materials such as polyurethane foam due to its innate moisture wicking properties.

- Blocking the Direct Line of Sight to Noise Sources: Blocking the direct line of sight to noise, like engine compartment components, by using barriers or insulation materials between the passenger area and the compartment helps minimize the noise experienced by those on board.

- Treating as Close to the Noise Source as Possible: Applying noise-absorbing materials like polyester fiber close to the noise source, such as the engine or generator set, helps prevent sound from traveling throughout the boat.

- Design Best Practices: Boat designers should also incorporate noise reduction best practices in boat design from the beginning. This involves considering the placement of noise-generating equipment, optimizing insulation and materials, and designing compartments in a way that minimizes sound transmission. For example, vibration isolation mounts help ensure that the boat doesn’t vibrate with the engine. In addition to generator sets and engine rooms, hull structures and floors should also be treated with noise-reduction materials.

Marine Noise Reduction Materials from Technicon Acoustics

Technicon has an extensive catalog of materials to help with all aspects of noise reduction in boat building and marine applications. They include:

- Vibration-damping materials: We produce vibration-damping materials, including rubber, polyurethane, and polyvinyl chloride (PVC) sheets. Determining the perfect material depends on the specifics of the boat and the marine application.

- Acoustic barriers: We produce mass-loaded vinyl (MLV) acoustic barriers, also called sound barriers. These are dense, sound-absorbing panels that help reduce airborne sounds transmitted through floorboards, enclosures, and other spaces on a marine vessel.

- Acoustic absorbers: Acoustic absorbers prevent sound from reflecting off hard spaces such as engine enclosures and operator cabs, creating uncomfortable noise levels in the room. For marine equipment, we make acoustic absorbers made of a blend of polyester fibers, offering low-frequency absorption properties, thermal resistance, and UL94 HF1 compliance.

Every product in our catalog is suitable for boat building and other marine applications. Our polyester fibers do not degrade in high-humidity environments, unlike foam noise-reduction products.

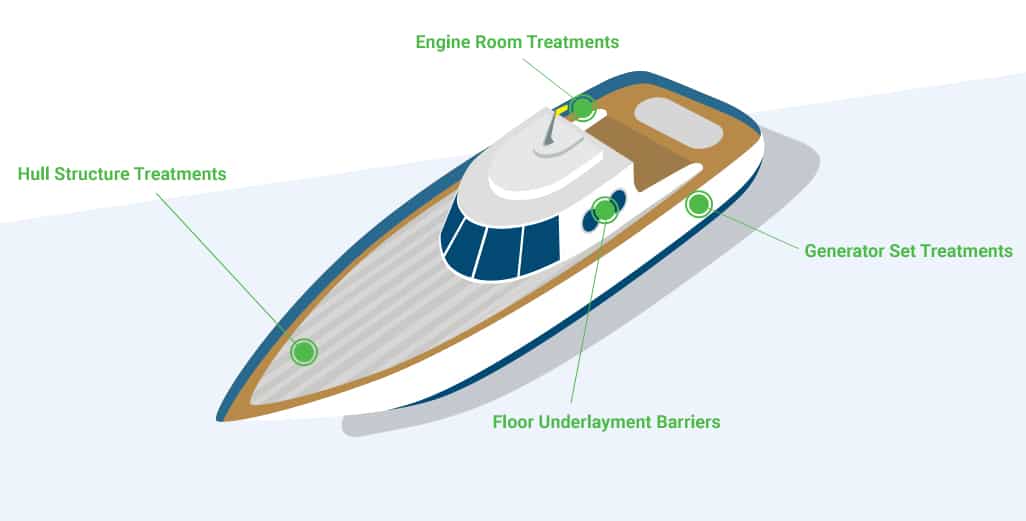

Engine Room Treatments

In many cases the engine room is the original source for most of the noise problems generated in the marine envrionment. Therefore, there are a myriad of treatment methods employed to minimize the negative impact that this unwanted sound and vibration can have on your customers comfort. Technicon can assist you at this design phase in order to ensure that appropiate acoustical design elements are considered prior to any construction. This is often the most economical way to avoid have a noise problem.

Generator Set Treatments

Generator sets have many of the same sound sound features as the main engine and should be analyzed for treatment in much the same way. Even if the generator set is already located within treated engine rooms, it may be necessary to further treat the genset. Placing the genset in its own enclosure isolated from the hull structure and lined with the appropiate acoustical absorber or absorber/barrier composite is recommended.

Hull Structure Treatments

In many cases, despite exceptional work done to minimize engine room noise impact on the hull structure, the hull itselft by the virtue of its contact with the external environment can be a major source of noise problems. Secondary engine or shaft vibration, propeller caviation or even fluid dynamics can set up resonate modes in the hull that cause the entire boat to act as a giant surrounding sounding board or drum. The proper vibration damping materials applied strategically to the hull or deck can effectively dampen the resonate frequencies of the hull and minimize the noise problem and significantly improve passenger comfort.

Floor Underlayment Barriers

Noise transmitting from engine or generator rooms can be a significant noise source on boats. The addition of floor underlayment, made of closed cell foam with a vinyl acoustic barrier, is a simple but effective solution to managing sound levels inside the cabin. Floor underlayment is designed to reduce the amount of sound transmitted through materials, which dampens noise and/or blocks it from entering the cabin. Our acoustic floor underlayments are available in a variety of sizes and can be custom cut to fit the floor.

Get the Best Marine Noise Reduction Materials from Technicon Acoustics

Technicon Acoustics offers high-quality noise reduction materials and solutions, allowing boat manufacturers to reduce noise levels in boats to meet NASBLA’s safe boating standards. Contact us today to learn more about our marine noise reduction solutions. You can also request a quote for a project estimate, or explore our PF-091 Noise Reduction Materials.