Vibration damping is a term used in ergonomic, industrial, and electronic applications where there is a need to lower the amount of energy a system produces. Once vibration has been damped, energy is transferred to appropriate channels and a reduction in noise propagation occurs.

There are myriad reasons why vibration may be undesirable. It may manifest as a simple annoyance or present a potentially catastrophic environmental factor.

Ready to Get Started?

Talk to an ExpertTypes of Damping Materials

At Technicon Acoustics, we rely on several different damping materials to ensure our products stop vibration before it becomes a problem. Determining which material is suitable for vibration damping is determined by the specifics of their intended application. Some of the most common vibration damping materials include:

- Rubber

- Polyurethane

- PVC

- Our Products

Let Us Help On Your Next Project!

Rubber is an ideal material for vibration damping applications. It absorbs energy before re-releasing it into the environment as heat, which helps quickly isolate vibration. While it doesn’t have true damping abilities on its own, it can be a powerful tool when paired with other materials. While rubber has minimal vibration damping effects, it does absorb energy and release it as heat, which makes it an ideal material for isolating vibration energy.

Polyurethane is a newer material option in the vibration damping space. More modern substances like foam and foam-like polyurethane products can absorb a system’s excess energy. Polyurethane products’ cell structures and densities can even be custom-engineered to fit specific applications.

Polyvinyl chloride sheets offer superior chemical resistance and serve to quickly absorb vibrations. These products are typically utilized as sound barriers, but may also be used to damp vibrations on enclosure surfaces.

We offer our clients a range of acoustic and vibration damping products, such as:

- PVC Damping Sheets with PSA – DM-200

- PVC Damping Sheets with PSA – DM-400

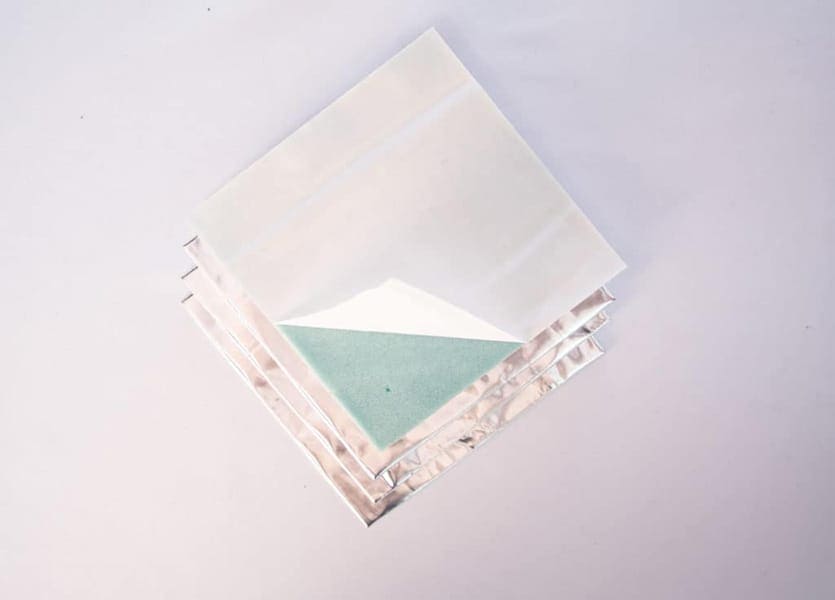

- Constrained Layer Damping Material – DP-100

- Tech Damp™

- Vibration Damping FD-100

Let Us Help On Your Next Project!

Leaders in Acoustic Material Manufacturing

Technicon Acoustics has operated as an industry leader in sound and vibration damping technology for many years. Our specialized line of sound and vibration damping products play an integral role in several key industries, including:

POWER GENERATION

We frequently customize professional noise control solutions for clients who manufacture portable and standby power generation equipment.

AUTOMOTIVE, HEAVY EQUIPMENT, AGRICULTURAL EQUIPMENT

We assist truck, bus, and specialty vehicle OEMs with sound and vibration control in their products.

MEDICAL

We assist OEMs in the medical equipment industry with sound and vibration control, ensuring optimal equipment function and patient comfort.

No matter your application, reduced vibration and noise improve the customer experience. That means improved quality perception and product acceptance rates.

Let Our Experts Help You Develop Your Noise Reduction Solution

At Technicon Acoustics, our team of qualified experts is prepared to help you take on any project. Whether you need help with material selection or you’re looking for advice on our products, we’ve got the answers you need to select the solution that’s best for you.

Vibration damping can play a critical role in improving your brand’s impression on customers. It may even increase your organization’s profitability.