At Technicon, we continually reinvest in the latest manufacturing technologies. These allow us to make the best products and materials as efficiently and productively as possible.

Value Added Services

At Technicon Acoustics, we offer a range of value-added services to provide a comprehensive solution to our clients. Our value-added services include:

JIT will increase efficiency and practice waste minimization by receiving goods only as needed.

KanBan inventory scheduling allows us to see the big picture. We use this technology to monitor and improve performance along with production flow.

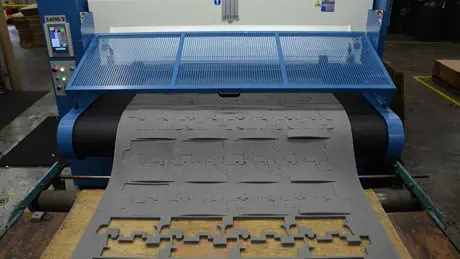

Our die-cutting and CNC-cutting capabilities enable custom kitting at high volumes. Custom-engineered designs can be cut into large pieces with perforated cuts and individually labeled for quicker receiving and a simplified inventory process.

Contact Technicon Acoustics for Your Next Acoustical Project

Technicon Acoustics has the production capabilities to deliver a comprehensive solution for your next acoustic project. We offer a variety of CNC cutting, lamination, and embossing services to deliver acoustic components that meet your requirements. Technion Acoustics also delivers in-house lab testing and value-added services to provide a complete solution.

Contact us or request a quote to speak with a team member about your needs.

Frequently Asked Questions

HOW LARGE IS YOUR FACILITY?

- 85,000 square ft.

WHAT CUTTING CAPABILITIES DO YOU HAVE?

- CNC Cutting

- Die Cutting

- Waterjet Cutting

WHAT LAMINATION CAPABILITIES DO YOU HAVE?

- Thermal and Flame Lamination

- Foam Embossing

- PVC Casting