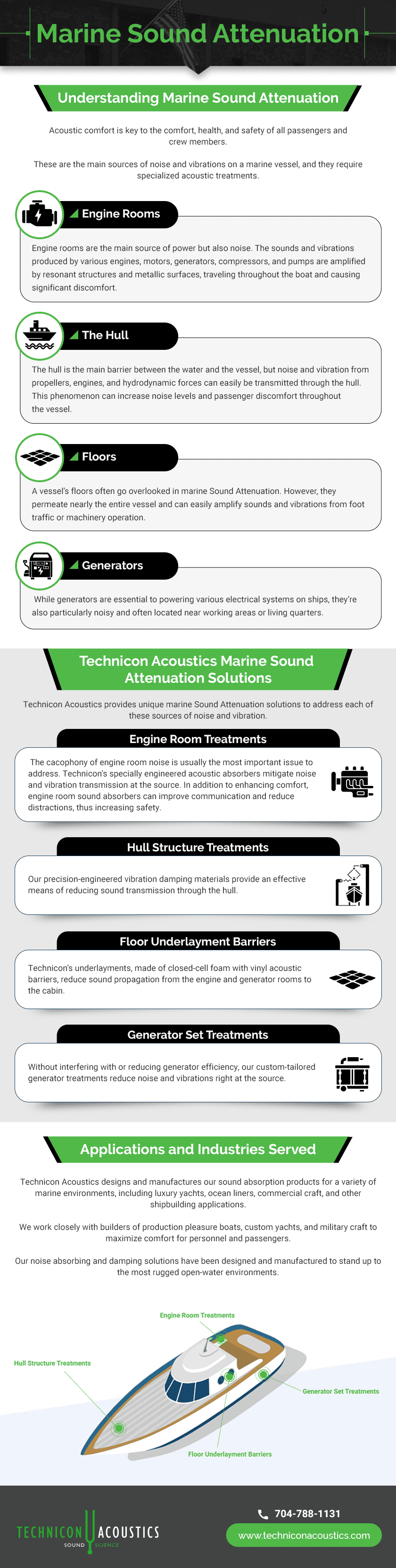

Marine Sound Damping With Technicon Acoustics

With impeccable quality controls and short lead times, Technicon Acoustics uses the latest design and fabrication technologies to develop superior sound absorption materials. Our additional expertise in heat shielding further enables us to produce effective sound absorbers, acoustic barriers, and vibration dampers for safe use near high-voltage equipment.

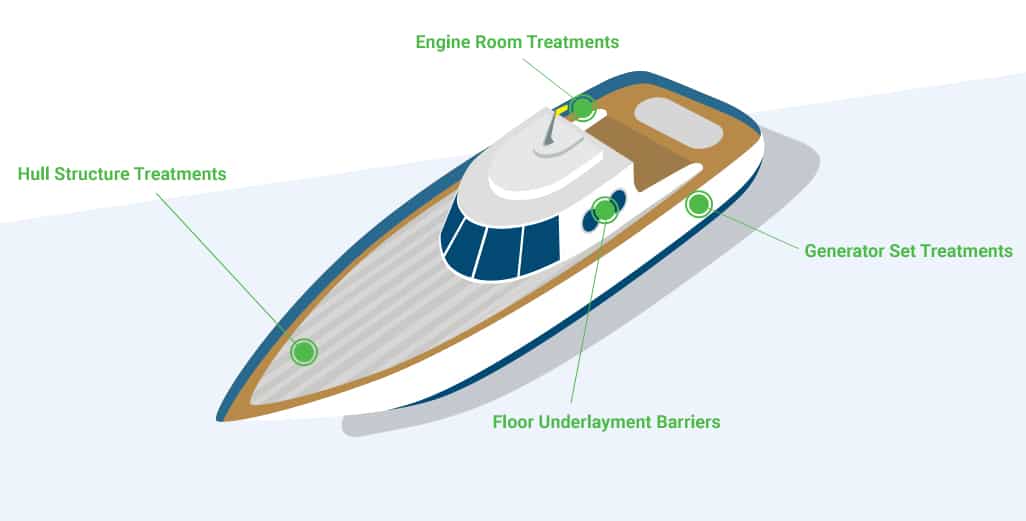

Marine sound damping creates a much more comfortable experience for vessel passengers and personnel. It also improves safety by making communication easier in working marine environments. To learn more about Technicon Acoustics’ specialty sound and vibration damping solutions, contact us or request a quote today.