Open Cell Foam vs. Closed Cell Foam

The material you select for sound insulation projects will significantly impact the level of sound absorption and attenuation you can expect to achieve. Open cell and closed cell foams are two effective material options for such applications, each with its own unique structure, benefits, and uses. Read on to discover how open cell and closed cell foams are both alike and distinct from each other to help decide which option is the right choice to address your acoustic needs.

Open Cell Foam vs. Closed Cell Foam Structure and Composition

Recognizable for its porous structure, open cell foam is constructed from an interconnected cell network that facilitates airflow for heightened breathability and air permeability. Its open cells also make the material more flexible. In contrast, the cells found in closed cell foam are sealed off, meaning that air and water can’t pass through them. Closed cell foam has a higher density, making the foam material quite rigid while offering enhanced capabilities for sound absorption and attenuation.

Performance of Open Cell Foam vs. Closed Cell Foam

While each foam type is advantageous in its own way, the following is an overview of open cell and closed cell foam performance:

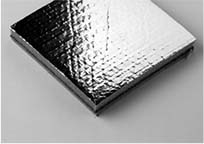

- Durability. Closed cell foam holds up better than open cell varieties, giving it good application versatility and the durability to handle insulation projects.

- Moisture resistance. Closed cell foam offers better resistance to moisture thanks to its impermeable structure. Open cell foam has a higher chance of developing mold because it runs the risk of absorbing and holding moisture.

- Thermal insulation. Open cell foam’s breathable, porous structure lends it to applications within controlled indoor environments. Conversely, closed cell foam is an optimal choice for outdoor applications and settings that will expose it to moisture due to its higher R-value.

- Sound absorption. Open cell foam exhibits superior sound absorption capabilities due to facilitating airflow within its cell network. Besides having a lower density, this material is softer and thicker, minimizing sound waves with greater efficiency than closed cell foam.

Closed Cell Foam Applications

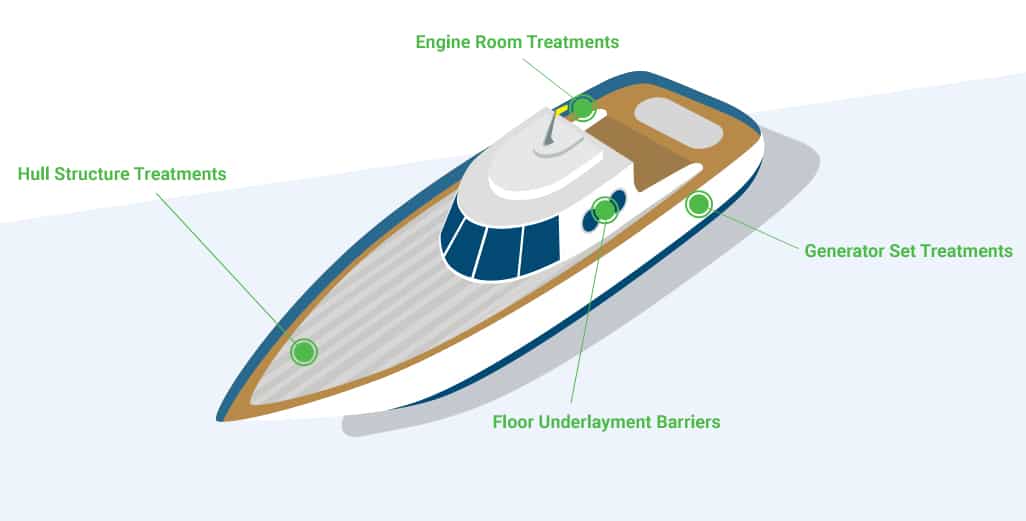

Between its sound insulative qualities and its ability to resist water, closed cell foam is ideal for applications like the following:

- Air security

- Ceilings

- Gasketing

- Insulation

- Mats

- Neoprene products

- Reinforcement for construction materials

Open Cell Foam Applications

Open cell foam is compatible with the above applications, as well. However, open cell foam achieves better air permeability, giving it additional applications in acoustic absorption and sound attenuation.

Acoustic Absorption

Two material options for open cell foam in acoustic absorption applications are polyether and polyester. Polyether foam is crafted from open cell polyurethane. Flexible and lightweight, this compressible foam offers impressive sound absorption as well as thermal insulation capabilities. Alternatively, polyester foam exhibits superior tensile strength.

Sound Attenuation

To reduce noise and noise pollution or dampen its transmission, open cell foam is a good choice for:

- HVAC systems

- Equipment enclosures

- Industrial environments

- Automotive interiors

Cost Considerations

Compared to closed cell foam, open cell foam is significantly less expensive as it requires less plastic material to manufacture. This translates to lower costs while providing the same degree of thermal insulation through the effectiveness of its air permeability as an insulator. Although open cell foams are more cost-effective per cubic foot, closed cell alternatives are more successful at maintaining their performance capabilities over time. Just be aware that for installing closed cell foam, you may need specialized equipment.

Acoustic Absorbing Foam and More From Technicon Acoustics

To choose between open cell and closed cell foam, evaluate the specific needs and environment of your application. Open cell foam offers good sound absorption and attenuation as well as air permeability at a more economical price. Closed cell foam is durable and water-resistant for outdoor environments.

As a leading manufacturer of innovative products for acoustic and thermal applications, Technicon Acoustics, Inc. has been supplying OEMs throughout North America with custom solutions for over 40 years. Our team understands the key elements to designing sound enclosures and related goods, so we offer acoustic absorbers and barriers, vibration damping products, and an array of films, facings, and adhesives to meet the versatile needs of clients in industries ranging from air compressors and power generation to medical devices and specialty vehicles.

Offering a lead time of two weeks and a quality control rating of 99.91%, we strive to create the Perfect Order Experience for our customers. Contact us for help deciding between open cell and closed cell foam, or request a quote today on one of our many product options.