Start to Finish with Technicon Acoustics

![]() A common problem for many OEM’s is excessive noise or heat that needs to be controlled. As a leading manufacturer of acoustic and thermal solutions, we are experts in creating solutions that absorb or block unwanted noise and heat. Technicon Acoustics is dedicated to not only finding the perfect solution for your product, but also to ensuring the entire process from development to delivery is pleasant and stress free. We provide quick lead times that meet your needs, expedite urgent orders, and find cost-effective and long-lasting solutions by understanding your needs and constraints.

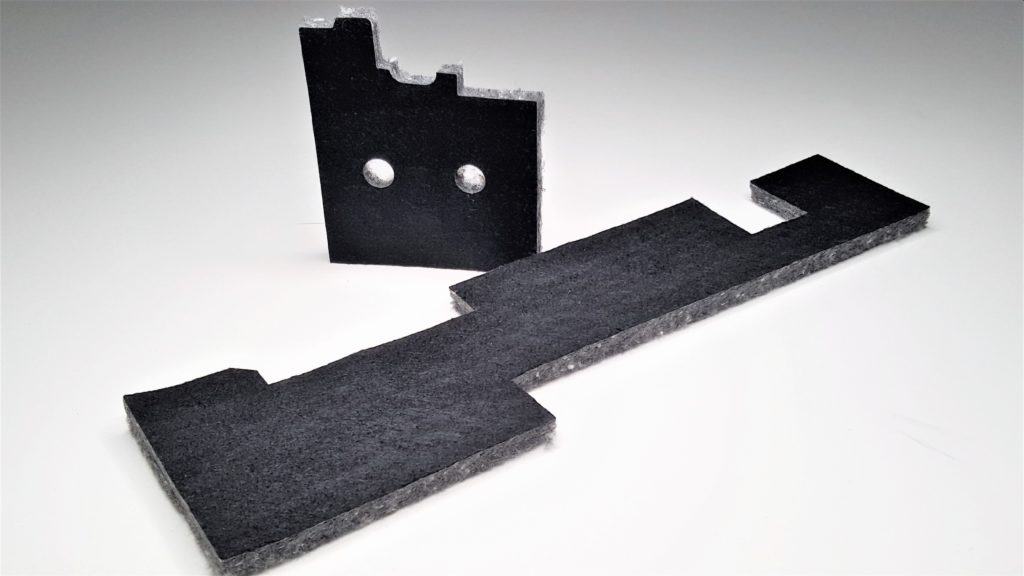

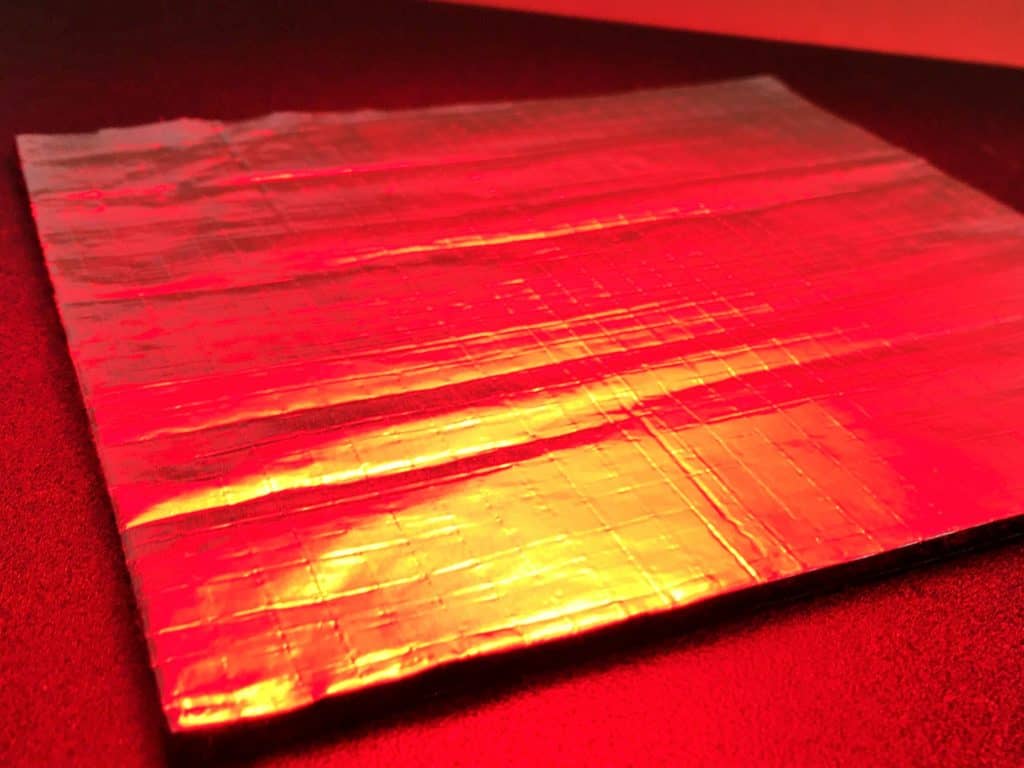

A common problem for many OEM’s is excessive noise or heat that needs to be controlled. As a leading manufacturer of acoustic and thermal solutions, we are experts in creating solutions that absorb or block unwanted noise and heat. Technicon Acoustics is dedicated to not only finding the perfect solution for your product, but also to ensuring the entire process from development to delivery is pleasant and stress free. We provide quick lead times that meet your needs, expedite urgent orders, and find cost-effective and long-lasting solutions by understanding your needs and constraints.

Technicon Acoustics supports your end-to-end product development needs. We ensure your satisfaction with the ordering process, material, manufacturing, and delivery of the final product.

Walkthrough Process/ Discovery Process

When customers reach out to Technicon Acoustics to solve a noise or heat problem, we want to understand their needs and expectations. We ask the customer to explain what they need from the product and how they want it to function. We follow up by requesting a description of the customer’s environmental conditions and any limitations that might affect product use. Finally, we ask the client what their goals are for the product.

Understanding the customer’s needs allows us to design a product to meet them. We may recommend an alternative to the customer’s initial request and make adjustments to facilitate the customer’s environment, limitations, and goals. After we have a thorough understanding of the customer’s needs, we send the client sample materials to evaluate.

Once the client is confident in the material selection, we create a prototype in full scale to allow the customer to test the final product. After evaluating the prototype, we create a bid package with additional options that the customer may want to include in the final product. Once accepted, Technicon Acoustics performs quality approval and inspection to ensure the product meets our quality standards and the client’s needs. From there, we begin manufacturing the custom product.

Our team also provides dedicated customer support and post-production support after the product ships to the client. Our knowledgeable team is committed to delivering responsive answers to customer inquiries and ensures accurate and on-time delivery.

The Order Process/ Execution/Committing to Quality

At Technicon Acoustics, we strive to offer the perfect order experience for our customers. This starts with our industry leading 2 week lead time and 99.16% on time shipping performance. Our OEM partners expect top quality from their suppliers. Technicon consistently delivers world class quality with a 99.91% performance score thanks to our ISO 9001:2015 quality standards and dedicated production team. Our goal is to be the low maintenance, top performing vendor for all of our OEM partners

Technicon Acoustics can also deliver the following value-added solutions to ensure our products meets the customer’s needs and expectations:

- Just-in-time (JIT) delivery to eliminate the need for on-site storage and potential waste

- Custom kitting using our die-cutting and CNC cutting services

- Simplified inventory management, labels for individual parts, and custom-made perforated pieces for efficient installation

- Improved production flow and performance using Kanban inventory management

Partner With Technicon Acoustics

Technicon Acoustics provides the best product by understanding the needs of our customers and building a custom product to fulfill their goals. Our customer service team strives to deliver the perfect order with the best ordering experience, and we welcome feedback to help us improve.

If you are interested in partnering with Technicon Acoustics, reach out and talk to our experts about your needs and goals today. You can meet our team to collaborate on the ideal solution and provide feedback to help us improve the design. We will finalize the design and deliver a product that meets your expectations. Contact us or request a quote to learn more about our made-to-order acoustic and thermal solutions.